Multiple steel types are used in the manufacture of the AR-15 barrel. So, which steel is the best AR-15 barrel material then? Some manufacturers prefer to use 4140 or 4150 steel while others prefer to use 416 SS or 416R steel for its properties. Some other manufacturers prefer to chrome-line the inside of their AR barrels and some do not. There are also manufacturers who utilize a carbon fiber sleeve to lighten the AR barrel and increase its rigidity. There are multiple options on the market so we are going to give you some more information on AR barrels and AR barrel steel types so you can make an informed decision when you purchase your AR-15 barrels.

4140 vs 4150

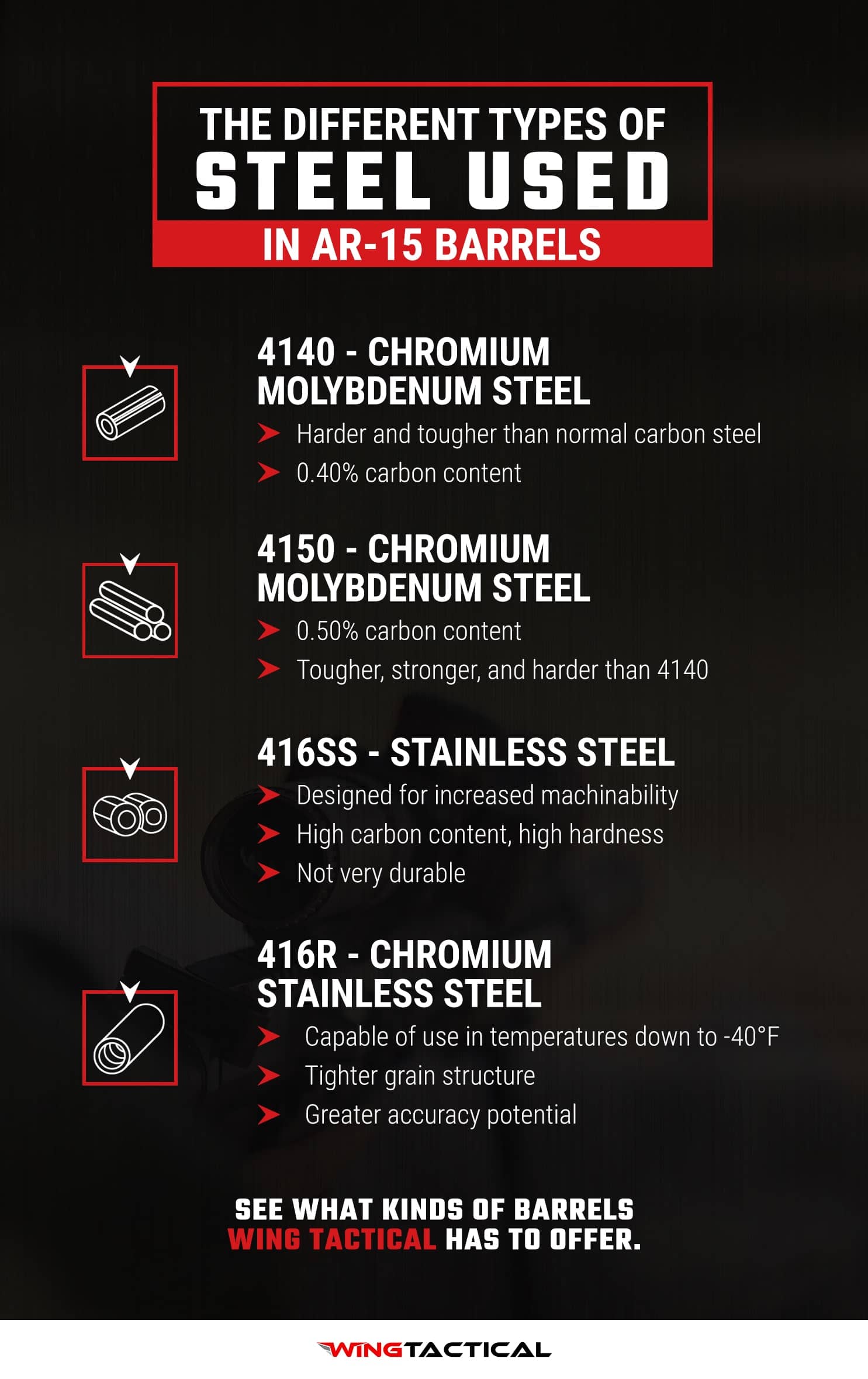

One of the more common barrel materials is 4140 and 4150. These common steels are very similar and only have slight differences. The 4140 AR barrel steel has the “41” for the first two numbers. Any steel with “41” as the first two numbers are known as chromium-molybdenum steels. These “41” steels contain 0.15% - 0.25% molybdenum and 0.80% - 1.10% chromium in their composition. The molybdenum and chromium ensure that these steel types are much harder and a lot tougher than normal carbon steel. Speaking of carbon, the last 2 numbers in the steel names (41”40” and 41”50”) are the amounts of internal carbon content. Meaning the 4140 steel has a 0.40% carbon content and the 4150 has a 0.50% carbon content. 4150 is generally used for parts that need to be tougher, have more strength, and higher hardness than 4140 can provide. 4140 is generally used for automotive parts that are normal sizes and require a decent amount of strength and hardness. Either would be a good choice for a barrel steel and would last you for a long time.

416SS vs 416R

When we talk about 416 vs 416R barrels, we need to break down the materials used in each barrel so we know the molecular profile of each steel. That will give us the information we need to choose our best AR barrel material. The 416SS (Stainless-Steel) grade steel is designed for increased machineability and high hardness. The 416SS barrels have a high carbon content that gives them a raised level of hardness, but the trade-off is that the other contents of 416SS can be lacking. 416SS is a good AR barrel steel for shooters who shoot once or twice a month, but it is not well suited for a competition shooter who will shoot hundreds or even thousands of rounds a month. On the other hand, 416R is a Crucible brand or “designer” steel. 416R chromium stainless steel was formulated by Crucible Steel just for barrel applications. Normal grade 416 stainless steel is not designed for use in colder temperatures, but 416R was designed to capable of use in temperatures down to -40F. Cold Steel anyone? Grade 416R Crucible Steel is designed with a tighter grain structure. The molecular profile of 416R gives it greater accuracy potential because of its ability to accept highly defined rifling, its ability to be lapped for increased smoothness and accuracy, and good toughness characteristics with high tensile strength. The 416R steel is what I prefer for my purposes, however if budget is a concern, than another option might be better for you.

Other AR-15 Barrel Materials

New materials and manufacturing techniques have made it possible to create specialized barrels with composite or multicomponent construction. Some of these popular barrel materials include:

- Aluminum: Aluminum makes a great lightweight AR barrel when chambered for the low-pressure .22LR. Most aluminum barrels have a steel liner to provide better strength and heat resistance. Aluminum alloy sleeves around steel barrels are also common on revolvers.

- Titanium: Titanium offers the strength of steel at about half the weight. With a steel liner, a titanium barrel provides excellent durability and heat resistance.

- Carbon fiber: Carbon fiber outer shells over rifled steel liners provide high rigidity, exceptional resistance and natural vibration dampening at a fraction of the weight of all-metal barrels. This material is ideal for ultralight rifles.

- Fiberglass: Fiberglass is extremely strong and heat-resistant. Like carbon fiber barrels, fiberglass barrels use a steel liner to provide the best combination of lightweight design and strength.

How to Choose the Best AR-15 Barrel Material

In conclusion, your choice of barrel material should center around a reasonable budget with realistic performance expectations and a decent understanding of what each barrel material is meant to do. Each of these common barrel materials has pros and cons, and each barrel material will ultimately serve you well for the given purpose. Also, keep in mind, you don’t have to just buy one barrel, you can purchase 2 or 3 types in different materials and profiles to try out and figure out the best combination for your needs. Determine what you are going to use the firearm for, ask your local gunsmith, read up on the materials, and make an informed decision. Be patient and shop smart, you’ll be glad you did.

Find the Best AR-15 Barrels at Wing Tactical

At Wing Tactical, our mission is to serve every type of shooter. Whether you're a civilian, law enforcement officer or military member, we have the high-quality parts and accessories you want.

Whatever your firearm needs may be, Wing Tactical has it — from grips to stocks to receivers and more. If you're looking to upgrade your AR-15 barrel, you can find one that fits your shooting goals in our high-quality, hand-picked selection.

When you buy your AR-15 barrel from us, you'll also benefit from next-day shipping options and 30-day, hassle-free returns to ensure you get exactly what you need as soon as you need it.

Browse our barrel inventory today or contact us for assistance. Our team of gun enthusiasts and experienced shooters will be happy to help you find the best AR-15 barrel for your new build.