AR-15 rifles are almost instantly recognizable due in part to their upper receiver profiles. AR-15 upper receivers have changed drastically since the introduction of the Armalite AR-15. Still, their primary functions remain the same: containing the bolt carrier group and charging handle, providing a means for manually closing the action, and cycling the action after firing.

The AR upper receiver plays an integral role in the rifle’s functioning. Shooters looking to customize their firearms often incorporate upper receivers (and other upper assembly components) that optimize performance.

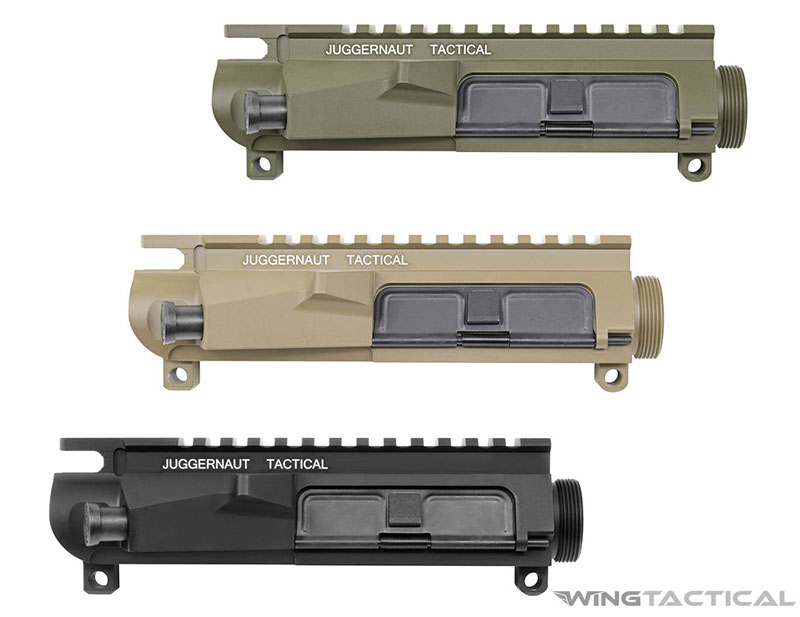

Upper Receivers for AR-15

Most of today’s AR upper receivers feature a distinctive Picatinny rail, a stable mounting surface for iron sights, optics, and other accessories. The rail only increases the modularity of the upper receiver and the entire rifle, swapping out parts and adding accessories to optimize rifle performance for specific shooting applications (like hunting, range practice, or home defense).

A complete upper receiver assembly includes a stripped upper, handguard, barrel, gas system, bolt carrier group, charging handle, and muzzle device. While shooters can construct their upper receiver assemblies from a custom selection of parts, Wing Tactical also offers complete upper receivers for builders looking to optimize time at the workbench.

Stripped Upper Receivers

For builders sourcing individual parts for a totally custom assembly, Wing Tactical offers stripped AR upper receivers that include housings without dust covers, forward assists, or bolt carrier components installed.

Gunsmiths looking to customize each component of their rifles should consider choosing a stripped upper and pairing it with compatible parts, choosing the right barrel, handguard, and charging handle to match their shooting applications and ergonomic preferences.

Assembled Upper Receivers

For builders looking for a happy medium between the highly hands-on stripped upper route and the user-friendly complete upper approach, Wing Tactical offers assembled AR-15 upper receivers with forward assists and ejection port doors already installed.

If they choose this product type, builders must still choose barrel and handguard products—or use the components that originally came with their rifles.

Complete Upper Receivers

Complete upper receivers are perfect for first-time builders, shooters looking to efficiently use their available build time, and beginner gunsmiths who haven’t yet invested in the specialized tools needed for assembling an AR upper receiver from various parts.

While they offer slightly less freedom of customization than their stripped and assembled counterparts, Wing Tactical offers complete upper receivers in a wide variety of configurations. If you’re looking for a complete upper receiver with a specific barrel length and caliber, one of our gunsmiths can help point you in the right direction.

Wing Tactical: Quality-First AR-15 Components

Wing Tactical is the rifle and handgun components and accessories source of choice for first responders, civilian gun enthusiasts, competition shooters, and active duty military personnel.

As a veteran-founded company, we understand that firearm dependability and performance are critical for both survival and safety. That's why every product in our catalog is thoroughly tested — we simply do not sell products that we wouldn’t use in our own builds.

If you’re building your first rifle, looking for a highly specific upper receiver configuration, or simply want tips from an expert, our dedicated team is happy to lend a hand. Reach out to our seasoned gunsmiths with all your build questions

Frequently Asked Questions

What’s in a fully-assembled AR-15 upper receiver?

A fully-assembled AR upper receiver includes:

- A handguard – Handguards protect shooters’ hands from contact with a hot barrel during repeat fire.

- A barrel – A barrel can impact your shooting performance, and it’s critical to the visual and functional character of your AR build.

- A gas block – A gas block collects gasses expelled from the action and barrel during firing and directs them to the gas tube. They’re essential to action cycling in gas-operated rifles.

- A gas tube – The gas tube cycles the action by diverting gasses back to the receiver.

- A bolt carrier group – The bolt carrier group includes the carrier body, bolt, firing pin, and extractor along with springs, pins, and gas rings. It’s one of the most complex components in an AR-15 upper receiver.

- A charging handle – The charging handle is pulled back to load a round in the action, and shooters often choose a handle design that meets their ergonomic preferences.

- A muzzle device – Muzzle devices can hide flashes, reduce recoil, and perform other specific tasks. Your shooting application and personal preference may influence your choice of muzzle device.

- The upper receiver housing – The upper receiver housing contains numerous components: the bolt carrier group, forward assist, charging handle, and dust cover (when one is used).

Which AR upper receiver is the most accurate?

While shooters must choose an upper receiver that accommodates the same caliber round(s) as the rest of their build, the upper receiver is less impactful on accuracy than other firearm components. Barrel construction and quality are perhaps the most impactful predictor of firearm accuracy.

Should you use a complete upper receiver or assemble one yourself?

Assembling an upper receiver from component parts requires some specialized skills and tools—vice blocks and barrel nut wrenches, for instance. Beginner gunsmiths or builders looking to save on tool costs might benefit from the convenience of complete upper receiver products.

But choosing a pre-assembled AR upper receiver won’t necessarily help shooters reduce their build cost, especially if they’re working on a highly custom configuration. Convenience and time efficiency are some of the chief benefits of opting for a complete upper, but either build route will offer a rewarding build experience.

Can you buy an assembled upper receiver without a barrel?

Yes. Wing Tactical offers both:

- Upper receivers with forward assists and dust covers already installed (without barrels or handguards)

- Upper receivers with forward assists, dust covers, and handguards installed (without barrels)

If you’re attracted to the convenience of a complete upper receiver but can’t find a pre-assembled product with the ideal barrel for your shooting application, the second option above might be the right choice for your build.

Do your upper and lower receivers have to be made by the same manufacturer?

In most cases, upper and lower receivers made by different manufacturers for the same AR platform rifle will be compatible. However, you should review the specifications of both assemblies carefully before purchase. If you need help choosing a compatible upper for your existing lower, our gunsmiths are happy to help.